Featured Past Articles

Peat is the most common material used in plant growing media, but have you ever thought about what peat really is?

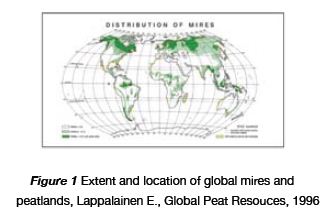

Organic Growing Medium Made By Nature Peat is a mixture of decomposed plant material that has accumulated in water-saturated bogs in the absence of oxygen. Peat formation is a continuous process, with bogs typically accumulating peat at a rate of 1-2mm every year. The rate of accumulating plant material is greatest in areas where the ambient temperature is high enough for plant growth but where the level of rainfall, specific topography of the landscape and low transpiration rates encourages waterlogging, limiting aerobic microbial activity which would normally break down the plant material.Such conditions are found more frequently in the northern hemisphere.

Peat is a mixture of decomposed plant material that has accumulated in water-saturated bogs in the absence of oxygen. Peat formation is a continuous process, with bogs typically accumulating peat at a rate of 1-2mm every year. The rate of accumulating plant material is greatest in areas where the ambient temperature is high enough for plant growth but where the level of rainfall, specific topography of the landscape and low transpiration rates encourages waterlogging, limiting aerobic microbial activity which would normally break down the plant material.Such conditions are found more frequently in the northern hemisphere.

Uses of Peatlands and Peat

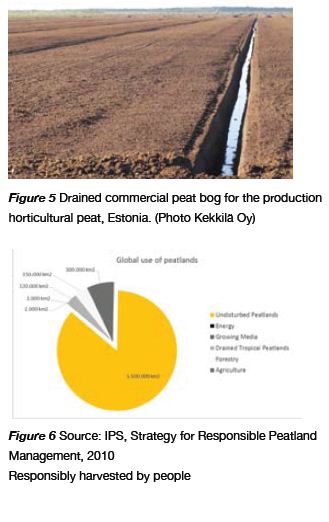

Peatlands are used and managed for many different purposes. Undrained peatlands are natural habitats for a wide range of endemic species of fauna and flora, and are a known carbon sink, locking up carbon released as CO2 into the atmosphere. As such, many bogs, particularly in Europe, are protected for their wildlife value, as well as their contribution to limiting climate change,with specific protection under national and European laws.

Historically,large areas of peatlands have been drained, and used for agriculture and forestry,as well as for the extraction of the peat itself. In the country of origin, extracted peat can be used as a local source of energy (biomass as a fuel for power plants), and for use in horticulture as a mayor constituent of growing media.

Peat is only harvested from carefully selected sites where specific extraction permits have been obtained from the local government of that area. These areas are selected, in part, because of their limited conservation value. Where areas are identified as having a conservation value, these are protected and not used for the extraction of peat. For example, in the European Union, peat extracted for fuel or horticulture is taken from just 0.4 % of all peatlands.

Out of all industries that have an impact on peatlands, including forestry and agriculture, it is the peat extraction companies who are regulated the most. For example, prior to starting to extract peat, it can take several years before all permissions are granted. The entire process from applying for the permit to actually extracting peat for the first time can take up to 10 years. This may include, as well as assessing the site at the beginning for its conservation value, having specific plans, and money set aside, to ensure that the bogs can be regenerated when the peat extraction ends.

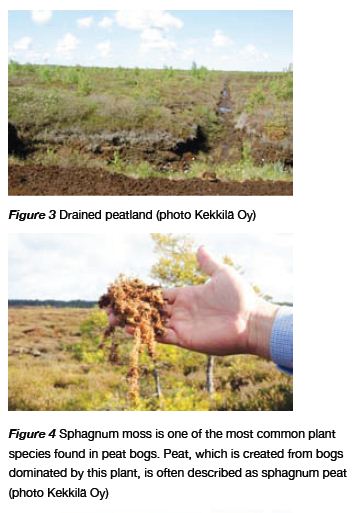

After obtaining the necessary permits, the first thing that is done is to create a series of ditches across the peatland to drain the water from the bog. This encourages the surface layers of peat to dry, and enable its extraction.Before drainage, a natural peatland has an extremely soft surface which prevents any equipment or machines to be used on the surface. It can take up to three years until extraction can start after the first ditches have been excavated.

Once the peat is ready to be harvested, this then takes place during only the summer months (roughly from May to September) when the weather is sunny and windy enough to help dry the surface layers of peat.

Peat for use in horticulture is extracted using two different methods. The first method produces the so called “milled peat”, and the second method produces “sod peat”.

Milled peat

During the harvest,1 - 3 cm thin layers of peat is milled or harrowed loose from the surface of the drained peat bog. After several days of drying under the sun, and when the peat is sufficiently dry (approximately 40-45% moisture content), it is collected directly from the surface of the peat bog by vacuum harvesters or, collected mechanically from ridges previously built.

Stockpiles of peat are formed at the peat bog and, by the autumn and winter, are covered with plastic foil. Finally, when required at the factory, the peat is transported to the production facilities, where it can be further processed.

Sod peat

During sod peat harvesting, big blocks of peat are dug out directly from the bog with special equipment up to a depth of approximately one metre. The sods of peat are left on the surface of the bog to drain excess water. When blocks start to dry in the springtime, they are piled manually in small piles to dry further, until they are dry enough to be processed in the substrate producing unit.

During the preparation and production of peat, the best available technology (BAT) is used in order to protect environment and ensure sustainable production.

When peat extraction finishes on a site, the area will be used for other purposes, which has usually been pre-determined at the point of receiving the extraction permit. The three main options for afteruse of a peatland are forestry, agriculture or re-wetting to create a new bog. Where bog regeneration is specified by the licencing authority, drains are blocked, and native plants are raised and planted to encourage the regeneration of a natural bog ecosystem.

Natural Pyrethrum: A Solution for Whiteflies, Aphids, Thrips, Mealybugs, Caterpillars, Mites, Bugs, Beetles, Scales and Many More

Growers are faced with challenges from pests ranging from pests in the soil that attack the root system to those that attack the stems, leaves or buds posing an economic damage or aesthetic damage to the crops and thus leading to low production yields.

The most commonly found pests on crops are whiteflies, thrips, diamond backmoth caterpillars, African bollworm caterpillars, beet armyworm, mealybugs, aphids, stinkbugs, mites, leaf hoppers, jassids, cutworms, beetles, ants and others. There are different methods of controlling these pests ranging from biological controls, cultural methods, physical methods and chemical controls.

Farmers prefer a pest control method that has a fast action to the pests though they put into consideration issues of efficacy, post-harvest intervals (PHI), maximum residual levels (MRLs), phytotoxicity, resistance, safety of predators, pre-entry time after spraying, human and environmental impacts particularly on crops such as vegetables, flowers and fruits; and whether for export or for local market. For the export market there are regulations on the kind of molecules to be used on different crops by the consumer markets and significant issues with MRL’s. One of the molecules that has been in use for years for the control of pests is the pyrethrin molecule. Pyrethrins are the active ingredients in pyrethrum derived from the dried flowers of the plant.

The advantages of using pyrethrum based products for control of pests are:

- Pyrethrum is 100% natural

- Low mammalian toxicity: No other insecticide can claim such a long record of proven safety towards humans and warm blooded animals. It is one of the least toxic of all insecticides and is rapidly metabolized if accidentally swallowed (in tests toxicity to rats was found to be 4,000 times lower than toxicity to the house fly).

- No resistance issues as insects lack immunity to pyrethrins because of the complex structure of pyrethrins and thus one can spray pyrethrins continuously. Pyrethrins have six active compounds called esters and thus attacks the pests from six different points.

- Broad spectrum activity: this means that it has an activity on all insect pests

- Has a fast action: it gives a knockdown effect on the insect as it works by contact and also by affecting the nervous system of the insect.

- Environmentally friendly: pyrethrum quickly breaks down in sunlight leaving no residues.

- No Pre-harvest Interval: this allows pyrethrum to be applied to crops up to and including the day of harvest. It may also be applied post harvest.

- Repellency action: it is capable of repelling insects in addition to knock-down.

- Very low Re-entry Period: After spraying, workers may return to the greenhouse as soon as the spray mist has settled.

- No Residues: Pyrethrum quickly breaks down in sunlight leaving no residues. This is particularly significant where MRL’s are an issue (typically with export vegetables and fruit)

Pyrethrins are usually confused with pyrethroids but they are different in that pyrethrins are natural while pyrethroids are synthetic or man-made; pyrethrins have six active compounds while pyrethroids have one and this makes pyrethroids far more likely to be exposed to resistance by insects. Pyrethrins have a unique ability to induce excitation behavior in insects, characterized by erratic and increased movement by insects. This has the benefit of ‘flushing’ the insects out of hiding places, resulting in increased exposure to the Pyrethrins. Synthetic Pyrethroids do not have this flushing effect. Pyrethrins are naturally broken down by UV rays and PH variances and therefore have shorter environmental persistence than synthetic Pyrethroids.

KAPI LIMITED, a company based in Nakuru has specialized in pyrethrum formulations since 1964. It formulates a pyrethrum product called Flower DS 4% EC for agricultural use. Made with Kenyan pyrethrum, Flower DS 4 EC is a 100% natural formulation using only natural ingredients. Flower DS 4 EC may be used for conventional spraying in spray regimes in order to minimize the chance of resistance developing with the other insecticides used in the spray regime. It is also ideal for use on crops controlled by MRL’s. Flower DS 4 EC is also suitable for organic farming.

WINROSE J. MARIA, Sales Manager Agricultural Insecticides, Kapi Limited,This email address is being protected from spambots. You need JavaScript enabled to view it., 0710615604

Undervalued, neglected resource

Undervalued, the soil has become politically and physically neglected, triggering its degradation due to erosion, compaction, salinization, soil organic matter and nutrient depletion, acidification, pollution and other processes caused by unsustainable land management practices. The irony is that the main culprit of soil degradation is the very thing that most relies on healthy soils: agriculture. Industrial agriculture’s intensive production systems, which rely on the heavy application of synthetic fertilizers and pesticides, have depleted soil to the point that we are in danger of losing significant portions of arable land.

It is estimated that on nearly one-third of the earth’s land area, land degradation reduces the productive capacity of agricultural land by eroding topsoil and depleting nutrients resulting in enormous environmental, social and economic costs. Most critically, land degradation reduces soil fertility leading to lower yields.

Mounting violence in Ethiopia has seen many killed, as protests against the government’s economic and human rights policies continues. The tensions at the heart of the crisis are systemic ones, yet what makes the violence particularly worrisome is that foreign investors have become prominent targets. Foreign businesses are being systematically attacked in protest of the government’s development-centric approach, with protesters citing land grabs and unfair competition as key issues.

Mounting violence in Ethiopia has seen many killed, as protests against the government’s economic and human rights policies continues. The tensions at the heart of the crisis are systemic ones, yet what makes the violence particularly worrisome is that foreign investors have become prominent targets. Foreign businesses are being systematically attacked in protest of the government’s development-centric approach, with protesters citing land grabs and unfair competition as key issues.

Foreign investor confidence in Ethiopia has been shaken following nearly a year of unrest, with the country’s government now admitting that many people have died as a result of police crackdowns and a deadly stampede in the country’s Oromia region.

Government estimates claim that around 40,000 workers at foreign companies have been affected by the disruptions; as cement, textile, flower, and agribusiness firms have been attacked. Popular sentiments that the benefits of growth are not being felt by all, combined with worries about foreign goods undercutting local producers has made Ethiopia a very dangerous investment locale.

Prime Minister Hailemariam Desalegn declared a six-month state of emergency in an attempt to quell the protests by ethnic Oromo and Amhara communities over a land dispute and political marginalisation. The unrest has caused millions of dollars worth of damage to foreign-owned businesses, including flower farms and other agribusinesses. The anti-government protests have dented the view that Ethiopia is a stable partner for investment, according to Emma Gordon, a senior analyst with research firm Verisk Maplecroft. “[Foreign] investors are very concerned with the situation in the country, with some already pulling out,” she said. “They were willing to look past the human rights [abuses] perpetrated by the security services, but it’s difficult to ignore them now.”

The crop protection industry is dominated by the large multinational agro-chemical companies. The biocontrol business is minute in comparison, with less than 10% of global sales of crop protection products. The future of the biocontrol industry is based on a range of interacting factors and difficult to predict the future, however many are suggesting that its future is likely to grow. There are numerous drivers for the use of biological control.

Pesticide resistance

Whether a pest or a disease, most organisms have the ability to become resistant to a large range of pesticides. This is often seen in the field where one season a particular pesticide works well and later the efficacy is not there. Resistance has been reported in many common groups of insecticides and fungicides.

There occurrence of resistance to a biological control is virtually unknown. For instance in Kenya the wide spread adoption of t

Governments and the regulators he use of predatory mites was mainly due the fact that many of the conventional pesticides were not working due to resistance.

Broadly around the global, the authorities are trying to reduce the reliance on conventional pesticides. For instance EU have launched an action plan which has the objective to reduce pesticides, in compliance with the EU’s Sustainable Use Directive.

The aim is to reduce the dependency of farms on plant protection products (up to 50% reduction in ten years), while at the same time maintaining agricultural production at a high level in both quality and quantity terms. Another and more dramactic example of how governments can affect the use of pesticides is that the EU has placed severe restrictions on the use of a number of Active Igredients which include imidacloprid (Confidor), thiaclorpid (Calypso), acetamiprid (Golan) and thiamethoxam (Actara) are likely to be under pressure for years to come and this will not only be reflected in the EU but also Kenya as well. For instance the UK supermarket has given notice to its suppliers world-wide. Therefore can biological control fill the vacuum left by the regulators withdrawing pesticides?

KRA Vs VD Berg Who will brink First

The taxman has accused a Naivasha-based company of restricting the sale of its flowers to its parent firm in the Netherlands to avoid paying taxes to the Kenyan Government.

The Kenya Revenue Authority (KRA) has claimed in court that Van den Berg Kenya Ltd (VDB-K) has been selling most of its flowers to its Dutch parent firm at extremely low prices to cut the amount of tax it can pay.

VDB-K has sued the taxman to stop a Sh1.1 billion demand it says the authority has grossly exaggerated. But the KRA says in-depth audits into VDB-K revealed that the company has been colluding with its parent firm to dodge taxes.

The KRA also claims that VDB-K failed to provide crucial information such as details of sales between it and its Dutch parent. The taxman adds that some of the documents provided were written in Dutch, making it hard to use a tax calculation method agreeable to both parties.

“In particular, VDB-K failed to give transaction details with customer names, flower varieties, sizes and prices which information was necessary to establish the end-customer buying price on transaction by transaction basis,” the KRA says.

Court order barring the KRA “VDB-K provided certain documents in Dutch language, described by its tax agents as casual agents invoices. A review of these documents revealed that the persons listed therein were the same individuals listed in the shared cost analysis,” says Mr Patrick Chege, a manager in the Domestic Taxes Department.

The Dutch-owned company has secured a court order barring the KRA from claiming the amount until Justice George Odunga has determined the suit.

By Joseph Muita

Powdery mildew is caused by a fungus called Sphaerothecapannosa, it is one of the most widespread and easily identifiable plant fungal disease. From vegetable gardens to rose gardens, ornamental trees and shrubs, almost no type of plant is immune even though the fungus is host specific.

What to look for

You’ve likely seen it many times. White or gray powdery spots appear, often times covering most if not the entire leaf surface. It’s also found on plant stems and flowers. Fortunately, the symptoms of powdery mildew are usually worse than the actual damage. Rarely is it fatal to the plant. Advanced stages can cause plant foliage to yellow, curl or turn brown and eventually cause the plant to defoliate prematurely. On flowering plants, the fungus can lead to early bud drop or reduce the flower quality and this kind of loss can be devastating for any grower, large or small.

Epidemiology

In greenhouses, roses and powdery mildew grow continuously. The disease cycle (production of spores, release, germination, infection, and production of conidia) can be as short as 72 to 96 hours. If left uncontrolled, powdery mildew can quickly become epidemic when suitable conditions for disease are present, but especially when rainfall is low or absent, the days are warm and dry, and the nights are cool and damp. Spore maturation, release, spread, infection requires: cool (16°C) + damp (RH – 90 to 99%) night followed by Warm (27°C) + dry (RH – 40 to 70%) days.

Symptoms

Symptoms first appear on the upper leaf surface. They are irregular, light green to reddish, slightly raised blister like areas shortly followed by the typical dense, powdery white growth (mycelium, conidiophores and spores) of the mildew.

Symptoms first appear on the upper leaf surface. They are irregular, light green to reddish, slightly raised blister like areas shortly followed by the typical dense, powdery white growth (mycelium, conidiophores and spores) of the mildew.

Young leaves become curled or irregularly twisted and are usually covered with enlarged, whitish gray powdery patches of the fungus. Also buds may become infected, initially with the typically flour like symptoms, if this is rubbed off the stems have brown patches but stays firm (this in contrast to botrytis)

Infection Process

Infection starts with spore landing on a leaf (or on the stem or the flower) No water is required for this since the spore consists of 70% water. Germination usually takes place at night in this period the Relative Humidity (RH) is generally higher than during the day. A high RH promotes germination, water drops on the leaves inhibit germination but after drying the leaf is more sensitive to infection. Dispersal takes place mainly by air movement and to a lesser degree by humans or animals. Sporulation takes place usually by day, around noon. The spores’ spread mainly by air movement and to a lesser degree by humans or animals and despite their own high moisture content, the spores do not live long and if they do not germinate on living plant material they may die within 2 or 3 days.

Controlling an existing problem

Powdery mildew is a huge challenge hence the need to explore some ways to keep this fungus from ruining your plants.

First and foremost, prevention is key. As the saying goes, “an ounce of prevention is worth a pound of cure”. Once it is in your environment it is very difficult to eradicate.

Should you find the need to react to an existing condition of powdery mildew, early detection provides the best way to contain and potentially eliminate the problem. There are many commercial products that are effective at containing the spread. However, eliminating an existing problem is not a given.

Most conventional products are made for prevention and control, not elimination of an existing infection. That’s why it’s important to start a control program before powdery mildew occurs or at least at the earliest sign of detection.

Cultural Practices

Getting rid of powdery mildew on roses can at times be a hard task so being proactive and getting out ahead of it through cultural methods like variety selection, providing good air circulation (bending), to avoid excess use of fertilizers, taking away fallen leaves, maintaining a healthy plant, last but not least to shower the leaves so as to kill the spores, but being careful not to raise the RH when you go into the night.

What’s the key?

Judging from the number of questions I get about powdery mildew, I’ve learnt three things over the years; 1.) It’s everywhere, 2.) You dread it, and 3.) You want to know how to get rid of it. So, here is what BASF offers as a perfect solution for Powdery Mildew Control.

The parting shot is that the best way to deal with powdery mildew on roses is to prevent it in the first place.

For more details Contact:

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.; Tel: 0786 856973